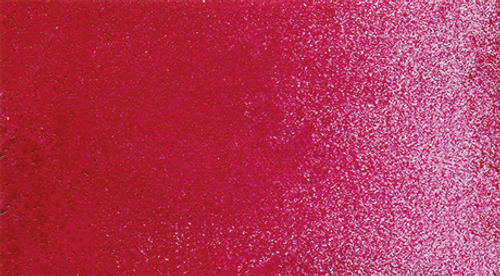

Description

500g Tin

Transparent

PB15:3 (C.I 74160) Beta copper phthalocyanine

PW18 (C.I 77220) Calcium carbonate

Drying time: Average

Transparent

PB15:3 (C.I 74160) Beta copper phthalocyanine

PW18 (C.I 77220) Calcium carbonate

Drying time: Average

For non-toxic printmaking or solvent-free cleaning.

Oil-based inks that wash away safely with liquid soap and water. Suitable for all types of relief or block printing, such as woodcut and wood engraving, letterpress and linocut.

This range contains less than 1% of driers. For faster drying rates, add a small amount of cobalt or manganese driers.

We always select light fast pigments for our formulations. All our inks are rated 6 or higher on the International Blue Wool Scale.

Oil-based inks that wash away safely with liquid soap and water. Suitable for all types of relief or block printing, such as woodcut and wood engraving, letterpress and linocut.

This range contains less than 1% of driers. For faster drying rates, add a small amount of cobalt or manganese driers.

We always select light fast pigments for our formulations. All our inks are rated 6 or higher on the International Blue Wool Scale.

See also RDC 63827 Caligo Safe Wash Relief Process Red ( Magenta) and YLC 91884 Caligo Safe Wash Relief Process Yellow. Our Process (or primary) colours can be used in several ways, for example:

1. Mix the three process colours in varying proportions to create a spectrum of bright colour mixes of your own. You will find you can make a much wider range of greens, purples, blues, reds and oranges than you can achieve with a standard blue, red and yellow ink. Use white and black and extender to make an even wider range of tints and shades.

2. Over printing layers of these inks to create new colours where the transparent coloured layers overlap.

3. For printmakers who need a four colour process set (CMYK) to create prints with multiple plates.

(Depending on ink film thickness , you can adjust strength with extender as required)

1. Mix the three process colours in varying proportions to create a spectrum of bright colour mixes of your own. You will find you can make a much wider range of greens, purples, blues, reds and oranges than you can achieve with a standard blue, red and yellow ink. Use white and black and extender to make an even wider range of tints and shades.

2. Over printing layers of these inks to create new colours where the transparent coloured layers overlap.

3. For printmakers who need a four colour process set (CMYK) to create prints with multiple plates.

(Depending on ink film thickness , you can adjust strength with extender as required)

Extra Information

Brand:

Cranfield

Process / Medium:

Relief

Cleanup:

Water

Size:

500 gm tin